Permanent Photo-patternable Epoxies & Polymers

Request a sampleKayaku is a leading provider of photoresist and specialty chemicals for MEMS and Microelectronics, in particular in the field of permanent photo-patternable epoxies and polymers such as: SU-8 epoxy-based photoresist - KMPR® 1000 i-Line epoxy based photoresist - PermiNex® 1000 and 2000 Wafer Bonding Adhesives - KMSF® 1000 Low Stress Dielectric Photoresist.

Avez-vous une question? Contactez-nous

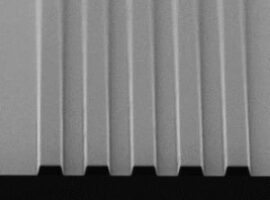

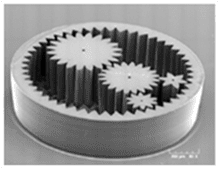

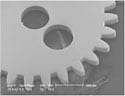

SU-8 negative epoxy-based photoresists

SU-8 resists are high-contrast, chemically amplified, epoxy-based resists that are highly functional and photo-imageable using near UV (365nm) radiation. Cured films or microstructures are highly resistant to solvents, acids and bases and have excellent thermal and mechanical stability, making them well suited for fabricating permanent structures such as pixel walls, fluidic channels and nozzles, micro arrays and spacers.

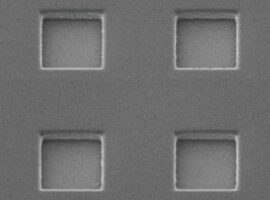

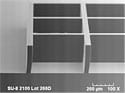

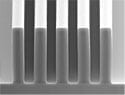

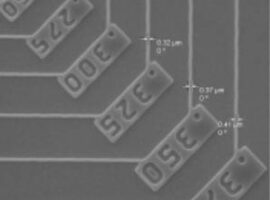

KMPR® 1000 i-Line epoxy based photoresist

KMPR® 1000 i-Line photoresist is a high contrast, epoxy based photoresist that can be developed in a conventional aqueous alkaline developer (TMAH). KMPR® 1000 is designed to coat 4-110 µm in a single step using five standard viscosities.

KMPR® 1000 can be easily removed after completion of electroforming using commercially available chemical removers. Lithography can be used to form KMPR® 1000 molds that have the required dimensional accuracy and sidewall verticality for micro electroforming.

Deep reactive ion etching (DRIE) compatible with the CMOS process, KMPR® 1000 will survive dry etch for the extended periods of time necessary to perform >20 µm deep etching with HAR.

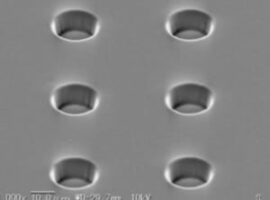

PermiNex® 1000 and 2000 Wafer Bonding Adhesives

Kayaku Advanced Materials, Inc. PermiNex® 1000 and 2000 resists are epoxy based, photo-imageable bonding resist used as an adhesive layer for the definition and capping of cavity structures such as BAW, SAW, microfluidic devices, and others, where critical alignment, low temperature processing and high bond quality are desired.

KMSF® 1000 Low Stress Dielectric Photoresist

KMSF® 1000 is a negative tone, polyimide-based photo-dielectric for use as an ultra-low stress buffer, passivation or protective layer.